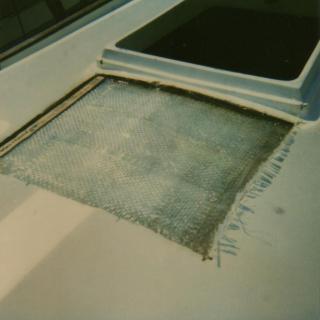

A common problem on newer Alberg 30's is compression of the balsa core at the mast-step. Details on methods of repair to the deck have been covered extensively in the A30 Maintenance Manual for both older and newer boats. Following these guidelines, I made the following notes during of my repair to #499.

On Things to Do:

If you're doing the top down repair, consider making your repair area as small as possible. This will keep as much of the outer skin in tact as possible and make your cosmetics that much easier later on. Take the time to tape and mask all surrounding areas. I mean everything near by. I made a mess everywhere. The only thing more messy than epoxy is 3M5200. If you're not interested in recreating the non-skid pattern later on, consider sanding the nonskid smooth, or covering with a thin layer of epoxy and then using an after-market paint/ non-skid product to cover your repairs.

To route out the glass and core, use a router with a Carbon steel bit. These are the monster looking router bits at Home Depot, mine are industrial yellow. Don't even waste your time trying to use Black n' Decker regular router bits they'll go dull in the first ten minutes and start smoking.

For coring material, use Kleg-cell fiber mat foam from a company called Fiberglass Coatings, Inc 1-813-327-8117, website www.fgci.com. The stuff is not that expensive, and although I didn't use it, I wish I had. I used pieces of hard wood. The problem with hard wood is that you have to make the pieces small enough to get the camber of the deck right. To create the mast-step pad I laminated four pieces of 9" x 6" x1/8" thick peg board using fiberglass resin. I was very pleased with the results.

Apply some kind of weight to the coring material and mast-step pad when you laminate them to the deck. This will ensure good contact with the deck camber. Be sure to use wax paper or a fiberglass releasing agent so your weights aren't permanently glassed in place!

This project is fairly complex, so allow enough time. As usual I underestimated the time it would take. I expected it to get done in a few weekends--It took over nineteen months. It takes time to do it right, I think. And you want to consider some kind of covering, like a small awning to allow you to work throughout the day, in light rain, and maybe direct sunlight. In any case re-build the mast-step in stages, and allow plenty of time for each layer of fiberglass to dry.

On things not to do:

Don't make the repair too small or too big. While the actual damaged core area on my boat was maybe 8" x 12", I went overboard and cleared an area 2x2'. Way too much. But 8" x12" is also too small. You're trying to strengthen the whole area remember. So route clear into solid core and establish a broad repair base.

On another note, don't use a flat bladed screw driver to try and chisel/pry out pieces of glass or core. Use a extra wide wood chisel, please!! I punched a hole through my liner using a screw driver.

Don't use just resin and coring material for the repair. You need a filler mixed with the resin to beef it up. Otherwise you'll go through a gallon on resin before you know it. Mix it up with the heaviest filler adhesive you can find.

Get all the information you can. You really need a consensus of information--like from the Maintenance Manual--to plan your rebuild strategy.

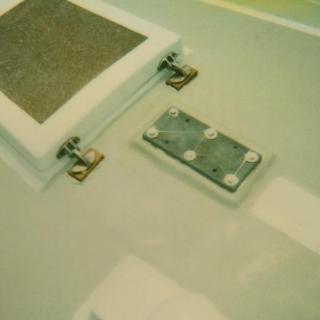

On the Thru-Bolt Installation:

I decided to thru-bolt my mast-step pad and plate, using six 3/8" x 3" long hex head bolts. The four aft most bolts go right through the deck, and can be bolted below. The two forward most bolts go through the forward beam (on the newer boats). I filled their wells with epoxy and 3m5200. I used stainless washers on both sides of the bolts, with liberal amounts of 3m5200 to prevent corrosive contact and water leaks. Below, a 1/4" thick stainless steel plate serves as a backing plate.

|

Offshore Sailing

by Bill Seifert with Daniel Spurr

We went to a Windjammers lecture to hear Bill Seifert and I was impressed enough to buy the book on the spot. I've heard a lot of people talk about ways to improve a boat, but I've never heard one person suggest so many good ideas that I hadn't considered. Part of the charm is the specificity of the suggestions. Everyone says you should secure your floorboards, hatchboards and batteries. Bill shows good suggestions on how to do so. The suggestions are very practical for the do-it-yourselfer, too. Many show how to make or adapt inexpensive solutions. Tip #12 on closing the deck blower vents is one that will pay off for me without ever going offshore. I'll implement that one to stop the wintertime storms from finding their way belowdecks. Besides modifications, the book also includes advice for operating offshore, cooking, boat selection, dealing with bureaucracy, and more. Bill Seifert has worked at Tartan, TPI, and Alden Yachts. He's a veteran of many Marion-Bermuda races and now runs his own yacht management company. His tips are born of experience--not of book-learning--and it shows. He obviously knows his stuff. (Note: commissions earned from this link help defray the costs of this website) |

- Deck Repairs

- Small Boat Patch

- Mast Beam

- Mast Step Deck Repairs

- Newer Hull Deck Joint

- Newer Taffrail

- Replacing Windows

- Adding Opening Ports

- Opening Port Gaskets

- Teak Hatch And Dropboards

- Cockpit Coamings

- Winter Cover

- Boarding Ladders

- Rub Rail

- Awlgrip

- Boat Maintenance

- Spars, Sails & Rigging

- Hull & Deck

- Deck Gear

- Steering

- Mechanical Propulsion

- Electrical

- Head

- Plumbing

- Accomodations

- Tools

- disorganized